A Biased View of Branded Screen Cleaning Cloths

Wiki Article

The Facts About Branded Screen Cleaning Cloths Uncovered

Table of ContentsThe Best Guide To Branded Screen Cleaning Cloths3 Simple Techniques For Branded Screen Cleaning ClothsLittle Known Facts About Branded Screen Cleaning Cloths.Branded Screen Cleaning Cloths Things To Know Before You Get ThisThe Basic Principles Of Branded Screen Cleaning Cloths

If the lenses are unclean or have actually not been cleaned for also long, utilize the adhering to actions. When washing, it is best to utilize a small amount of cleansing remedy and use your thumb and index finger in concentric circles to rub around the lens.By the individual regular appreciation. Because of the demands of top-quality family housing, some top-quality furniture requires to be well taken care of and maintained, to ensure that the senior clean class will certainly have a huge market area. There is a good market for wiping fabrics for toilets and cleaning cloths for interior cleaning.

Rumored Buzz on Branded Screen Cleaning Cloths

The number below shows one yarn weft knitting Warp weaved fabrics: Each row contains one or a number of parallel teams of yarns, with one thread forming only one (or 2) loops in a row. The photo below programs four yarns (environment-friendly, red, yellow, and white) Warp knitted textiles D. Knitting out the front and rear of the product pattern is not the very same, specifically weft weaved textiles.Single-sided weaved material: Knitted material knitted by one needle bed. The number over shows a single-sided knitted fabric Double-sided weaved mini textile: A knitted textile made from 2 needle beds.

The horizontal density is along the direction of the horizontal column of the coil, the number of longitudinal columns of the coil within a specified size (for example, 100mm). Longitudinal density is along the instructions of the longitudinal direction of the coil, the variety of straight columns of the coil within a specified length (as an example, 100MM).

See This Report about Branded Screen Cleaning Cloths

After the time is reached, we will leave the storage tank and make use of the dewatering maker to completely dry, and after that utilize the equipment to unfold the cloth that is twisted together, and ultimately utilize the maker to set the shape at high temperature level to make the textile level. Branded Screen Cleaning Cloths. If the shade requirement is high, we need to go back to the brand-new clear water container to rinse the color prior to drinking it dry to do away with the excess color or unsteady shade product connected to the surface area

b) Needle One (80% polyester and 20% nylon) and island silk (100% polyester): before coloring with needle two, we have to do an open fiber therapy first. It is to place the blank right into the alkali swimming pool at 130 degrees for about 30 mins so that the fibers of the visit this website blank explode (needle one is to destroy the nylon silk, and the island silk is to break the wall of each island-loaded fiber) to make sure that the surface area of the fabric is more cosy, the feel will be more combined.

Getting My Branded Screen Cleaning Cloths To Work

Before passing away, we have to do an open fiber therapy (as we stated at the door, the purpose of this is to make the surface of the material a lot more cosy, the feel will be much more blended), then in the dyeing tank dyeing, after reaching the specified time and temperature level out of the tank dehydration, and afterwards spread the cloth for shaping, and after that back to the dyeing tank to re-shape (due to the fact that the previous activity will certainly make the textile is stretched and deformed), and finally absorb the woollen and click now rolled heap.The fabric will do the brushing treatment on the textile after coloring. That is the surface area of the fiber filaments with maker rubbing, the surface area of its damage, so as to produce fine fluff so that the surface of the microfiber textile is softer. microfiber cleaning equipment guideline microfiber cleaning equipment it is to draw away the lint/flocking and dirt that are totally disappeared throughout the grinding procedure to ensure that the textile is cleaner and tidier.

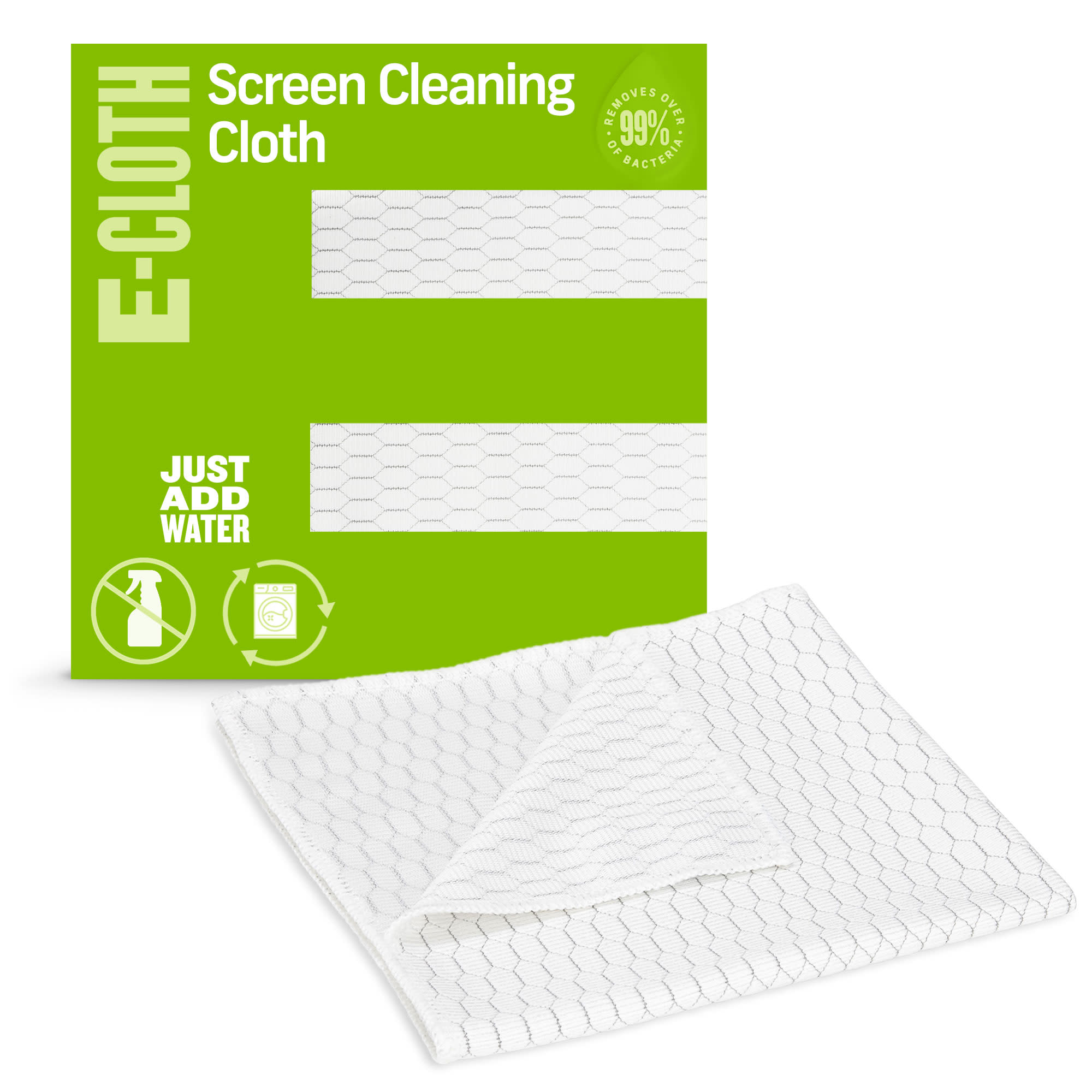

microfiber cloth rolling and evaluation Then reduced the entire roll of microfiber cloth into items according to the dimension required by each client (Branded Screen Cleaning Cloths). microfiber reducing equipment customized logo design procedure on each microfiber fabric according to the client's demand. The last point is to personalize the product packaging according to the demands of various guests

Branded Screen Cleaning Cloths Things To Know Before You Buy

Can be multi-color overlay printing, however the production rate is relatively sluggish, and the ink insurance coverage is reasonably difficult and a bit harsh. microfiber fabric silk printing Warm marking is under the activity of temperature level and pressure to make its product surface area and density adjustment, and the extruded material filled out the mold-shaped dental caries with undulating great lines convex, concave, and in the material, the surface area to obtain created undulating drum convex and text or pattern of a forming celebration.

Report this wiki page